dynamic indentation hardness test|example of hardness tester : suppliers An experimental technique for determining the dynamic indentation hardness of materials is described. Unlike the traditional static hardness measurements, the dynamic . webAssista vídeos pornô de Lesbicas Brasileiras Gozando de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta qualidade. Nenhum outro site pornô é mais popular e tem mais cenas de Lesbicas Brasileiras Gozando do que o Pornhub! Navegue pela nossa incrível seleção de de .

{plog:ftitle_list}

4 dias atrás · Find cheap home internet plans in Canada from $17/month with PlanHub. Compare prices, deals & promotions of 184 providers.

An experimental technique for determining the dynamic indentation hardness of materials is described. Unlike the traditional static hardness measurements, the dynamic .For example, dynamic indentation testing reveals a significant effect of loading rates on the hardness and the induced plastic zone size in metals and on the hardness and induced crack . The dynamic indentation test is used to simulate the impact between drill bits and rock surfaces. Short microwave irradiation (30 s) can largely reduce the diorite strength and indentation hardness. . Therefore, the dynamic indentation hardness index is defined as the ratio of the peak penetration force to the corresponding penetration depth .

wall moisture meter hire

With dynamic micro-indentation measurements, a probe is pressed into the sample using an electromagnetically controlled force while the penetration depth is monitored in real time using a differential transformer. .This document specifies the method of linear elastic dynamic instrumented indentation test for determination of indentation hardness and indentation modulus of materials showing elastic-plastic behaviour when oscillatory force or displacement is applied to the indenter while the load or displacement is held constant at a prescribed target value or while the indenter is .

• The dynamic indentation test is used to simulate the impact betw een drill bits and rock . Dynamic Strength and Indentation Hardness of a Hard Rock T reated by Microwave and the . In the original test proposed by Brinell, the load L is expressed in kilogram force. If L is measured in N (SI system), Eq. 1 should be divided by 9.8065. The full test load is applied for a period of 10–15 s. Two diameters of impression at right angles are measured (usually in the range 2–6 mm), and the mean diameter value is used for calculating the Brinell hardness . The hardness test is essentially a dynamic indentation test wherein the indenter is dropped from a fixed height onto the surface of the material being tested. The height of rebound is then a measure of the hardness of the material. . This Dynamic hardness testing of metals 75 problem could be further overcome by the use of a spring-loaded .

The mechanical properties attained via the indentation testing are in good correlation with results from conventional destructive tests and thus show practicability and applicability for stock rail characterization and/or railway track inspection, as well as other in-service static structures. . A simple theory of static and dynamic hardness . To determine dynamic hardness, the indenter is forced under high loading rate which leads to impact or chock the test material. Thus, the indenter could be shot the tested material like a projectile onto the target surface (Low 2006; El-Ezz 2007).The test material must be permanently deformed, so the kinetic energy should be chosen to assure plastic .

The dynamic indentation response of several ductile metallic materials [Al(111), polycrystalline copper, Fe, and Ti6Al4V] has been investigated using a pendulum-based nano-impact test. The impact process involves repetitive contact cycles until finally coming to rest in the material. Each cycle includes four phases: acceleration, indentation, rebound, and . 2. (a) The testing procedures described in the literature often were developed for specific purposes and do not specify certain conditions, e.g. the range of indentation (the depth of a crater or the maximum load).To reduce the number of factors affecting the results, a standard indentation test procedure is proposed. The standard testing procedure is in line with the .Rebound hardness, also known as dynamic hardness, . inferring the latter from the former is far from simple and is not attempted in any rigorous way during conventional hardness testing. (In fact, the Indentation Plastometry technique, which involves iterative FEM modelling of an indentation test, does allow a stress-strain curve to be . Indentation hardness is what engineers and metallurgists usually refer to when they talk about hardness. Measuring its value is of primary interest as continuous loading is the most common form of loading metals are subjected to. . An indenter is a reference material used for hardness testing. Dynamic hardness is usually measured by dropping .

This Dynamic Ultra Micro Hardness Tester measures dynamic indentation depth, not the indentation after the test. This in turn permits measurement of very thin films and surface (treatment) layers that are impossible to measure with conventional methods. Additionally, this same method supplies the data needed to calculate elastic modulus on the test specimens.indentation hardness test is due to the speed and simplicity with which it can characterize a material. . a dynamic indentation test is shown in Fig. 3(b). Due to the complexities involved in analyzing the nature of wave propagation within the conical shaped indenter assembly, the indentation force on the specimen cannot be easily deter .

2.2.1 Oliver and Pharr Method (O&P Method). O&P method is the most widely used model in nanoindentation technique. Typical indentation load–displacement curve and indentation profile before and after unloading process are shown in Figs. 2.1 and 2.2, respectively [].As the indenter is driven into the material, elastic deformation firstly occurs on .

Metallic materials — Instrumented indentation test for hardness and materials parameters — Part 1: Test method 1 Scope This part of ISO 14577 specifies the method of instrumented indentation test for determination of hardness and other materials parameters for the following three ranges: — macro range: 2 N ≤ F ≤ 30 kN; : A depth sensing indentation hardness test with an associated analysis is described as a convenient and simple technique for characterizing mechanical properties of food materials, such as hardness (H), elastic modulus (E), and an elasticity index (IE), which represents the ratio of elastic to total deformation. Storage modulus (G′) and loss tangent .ISO 14577 (all parts) has been prepared to enable the user to evaluate the indentation of materials by considering both the force and displacement during plastic and elastic deformation. By monitoring the complete cycle of increasing and removal of the test force, hardness values equivalent to traditional hardness values can be determined.

According to the test results, it was revealed that the correlation coefficient between the values of stress at yield and hardness, obtained by the method of dynamic instrumental indentation, is 0 .A hardness test that applies the load using an indenter on the material’s surface to cause an indentation is often known as a static hardness test. . Interestingly, the first dynamic hardness test came into the limelight in the early twentieth century using the Scleroscope to test material hardness. One example of this hardness test is the . The effect of strain rate (from quasistatic, 10 −2 1/s to highly dynamic, 10 7 1/s) on hardness of single-crystal Al is shown in Fig. 6 (b), which includes hardness value obtained from quasistatic indentation (this work and literature [35], high-strain rate indentation (initial strain rate >10 4 1/s) from literature [55], and ultra-high .

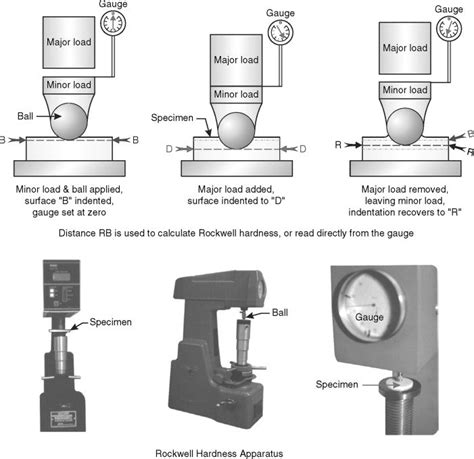

Dynamic indentation measurements notably offer the advantage of measuring hardness and modulus over the depth of a sample as well as viscoelastic properties. . (2015). ISO 14577-1 Metallic materials -- Instrumented indentation test for hardness and materials parameters. Geneva: ISO. ASTM International (2015). ASTM E2546 - 15 Standard Practice .Explore the different methods of measuring material hardness, including scratch, indentation, and dynamic hardness tests. Understand the principles behind the Brinell, Meyer, Vickers, Rockwell, and Microhardness tests, and their applications in engineering and metallurgy. . The first widely accepted and standardized indentation-hardness test .The iNano ® nanoindenter makes measuring thin films, coatings and small volumes of material easy. The accurate, flexible, user-friendly nanoindentation testing instrument can perform a wide range of nanoscale mechanical tests including indentation, hardness, scratch and universal nanoscale testing.

Semantic Scholar extracted view of "Dynamic hardness testing of metallic materials" by D. Leeb. . The article is devoted to modification of the impact devices of Leeb hardness testers for the implementation of the dynamic instrumented indentation method. The results obtained made it possible to . Expand. 5

The listed parameters of the indentation process allow us to measure the contact and volume hardness, the elastic modulus and the yield strength of test objects with portable hardness testers. The article is devoted to modification of the impact devices of Leeb hardness testers for the implementation of the dynamic instrumented indentation method.Supports a Wide Range of Testing Methods Record the relationship between the test force and the indentation depth. Test both the unload and load processes. Use the DUH-211S to perform cyclic load-unload tests and step load-unload tests. Supports Vickers Hardness Test function to measure the length of diagonals is provided as a standard feature.

principle of hardness tester

webAssista vídeos pornô de Putinhas Brasileiras de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta qualidade. .

dynamic indentation hardness test|example of hardness tester